HIGHLIGHTS

- Cycle view is useful when looking at operational decisions because it specifies the role of each member.

- The push/pull view of the supply chain is useful when considering strategic decisions regarding supply chain design.

- In addition to the two main approaches above, businesses can also approach from a macro perspective (Supply chain Macro Processes).

FULL ARTICLE

There are two main approaches: cycle view and push/pull view.

Cycle view of supply chain processes

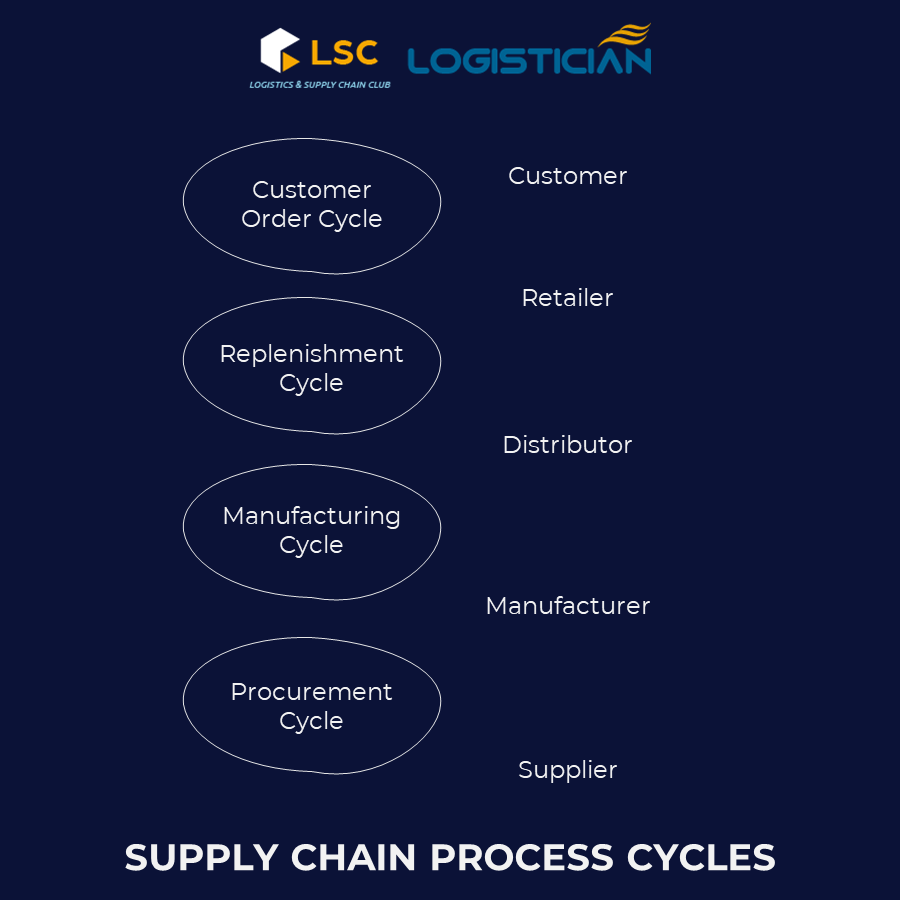

Supply chain activities are divided into four major cycles:

- Customer Order Cycle

- Replenishment Cycle

- Manufacturing Cycle

- Procurement Cycle

Each cycle occurs at the interface between two successive stages of the supply chain. There is not always four cycles clearly separated. For example, Dell bypasses distributors and retailers that all products are made to customer order with a 5-day delivery.

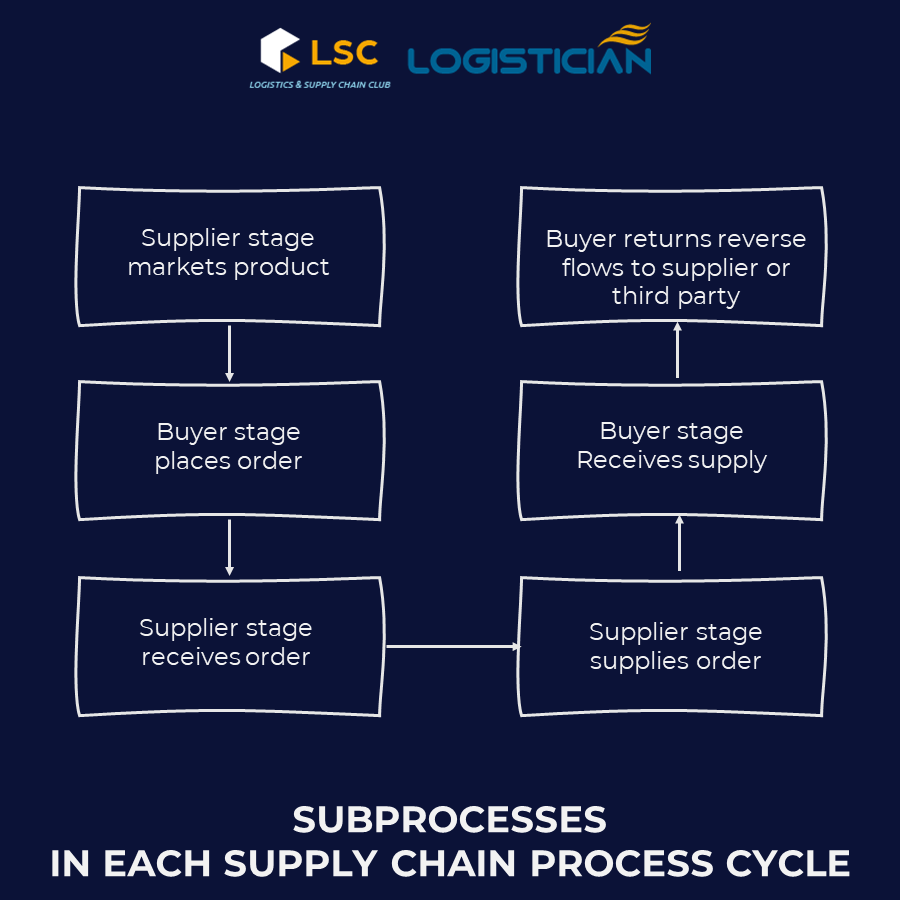

Each cycle consists of six subprocesses, including:

- Step 1: Supplier stage: markets product

- Step 2: Buyer stage: place order

- Step 3: Supplier stage: receives order

- Step 4: Supplier stage: supplies order

- Step 5: Buyer stage: receives supply

- Step 6: Buyer returns reverse flows to supplier or third party.

Depending on the transaction in question, subprocesses can be applied to the appropriate cycle. When customers shop online at Amazon, they are part of the ordering cycle, with the customer as the buyer and Amazon as the supplier. In contrast, when Amazon orders books from a distributor to replenish inventory, it’s part of the replenishment cycle, with Amazon as the buyer and the distributor as the supplier.

This approach is useful when looking at operational decisions because it specifies the role of each member of the supply chain. It therefore forces the supply chain designer to consider the infrastructure needed to support these processes.

Push/Pull view

All processes are segmented according to the time it takes to execute them relative to the needs of the end customer. With pull processes, order fulfillment is based on forecasts of customer demand and often applied in markets where buyer tastes are not clearly understood. With push, order fulfillment is initiated with a prediction of customer orders based on forecasts and applied in markets where customer tastes are known.

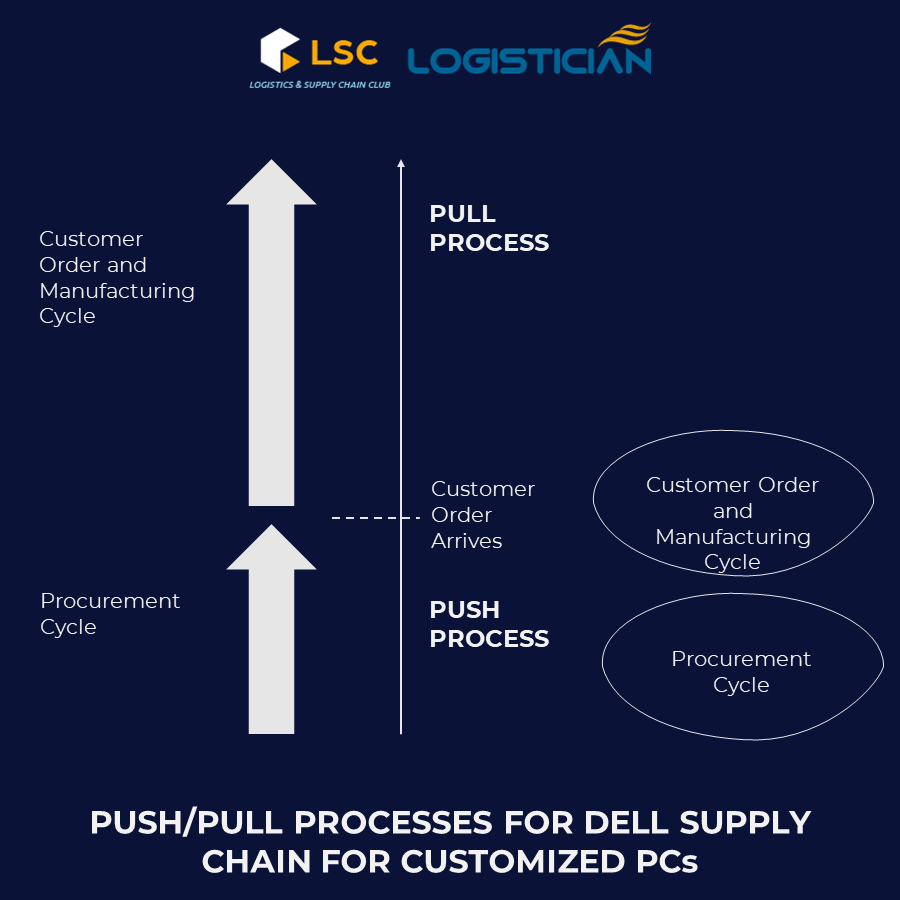

For example, in Dell’s supply chain, the “buyer orders and assembles factory” activities are Pull processes because only when the buyer places an order does the factory begin to assemble, manufacture, and deliver to the customer. “Purchase of raw materials” activities are push processes because they are performed before the buyer places an order and Dell does it based on the customer demand forecast.

The push/pull view is useful when considering strategic decisions regarding supply chain design. The goal is to define an appropriate push/pull boundary so that the supply chain can effectively match supply and demand.

The coatings industry is also an example of how it benefits from adjusting push/pull boundaries appropriately. Paint production entails base production, matching colors, and packaging. Until the 1980s, all these processes were carried out in large factories before shipping to stores. Therefore, paint mixing operations are part of the push process, as they are performed in anticipation of customer demand.

But in fact, demand is not stable, the paint supply chain faces many difficulties in matching supply – demand. In the 1990s, there were restructured, in which color mixing was done at retail stores after a customer placed an order. In this case, paint mixing operations are part of the pull process. Customers can always choose the paint color they want, while total paint inventory across the supply chain has been reduced.

In addition to the two main approaches above, businesses can also approach from a macro perspective.

Supply chain Macro Processes (CRM, ISCM, SRM)

There are 3 main areas that show the enterprise’s relationships

Customer Relationship Management (CRM):

- Manage activities between businesses and customers (advertising, sales, promotions, etc.)

- Objective: meet customer needs, manage and track orders.

Internal Supply Chain Management (ISCM):

- Manage internal company operations (planning of warehouse locations and sizes, making inventory regulations, etc.)

- Objective: to meet the demand generated by the CRM process in a timely manner and at the lowest possible cost.

Supplier Relationship Management (SRM):

- Manage activities between the business and suppliers (suppliers evaluation and selection, negotiation of supply-related issues, suppliers, etc.)

- Objective: to organize and manage the supply of products and services.

For a successful supply chain, it is important that the three macro processes are well integrated.

Minh Ngo