HIGHLIGHTS

- Uniqlo supply chain management prioritises building strategic relationships with high-quality and innovative Japanese partners.

- Uniqlo advocates outsourcing the entire manufacturing process to an exclusive third party.

- Unlike Zara, which uses a centralized distribution system (all products will be gathered at 4 distribution centers in Turkey), Uniqlo uses a regional distribution system, mainly in Asia.

- Uniqlo is expanding its online-to-offline (O2O) services to combine a physical store and an e-commerce network.

FULL ARTICLE

Procurement

To ensure the supplier of high-quality, stable and cost-effective materials, Uniqlo negotiates directly with suppliers worldwide and places orders in bulk to achieve economies of scale.

With “long-term fashion” strategy, Uniqlo focuses on building strategic relationships with high-quality and innovative Japanese partners. Specifically, it cooperates with Kaihara Corporation to supply denim fabric or Toray Industries, the world’s leading synthetic fiber producer, to create new yarns and materials such as HEATTECH.

Operations

Pursuing the philosophy of minimizing costs and maximizing efficiency, Uniqlo advocates outsourcing the entire manufacturing process to an exclusive third party. Each outsourcing factory only produces a certain type of clothing, making it easier to control quality.

According to Uniqlo, in South Asia and Southeast Asia with 242 factories in 11 countries. China accounts for more than half, with 128 locations. Vietnam ranked second with 44 factories. Next is Bangladesh with 24 factories. The company also has garment factories in Cambodia, Indonesia, Myanmar, and Sri Lanka, as well as six factories in India, where Uniqlo will open its first store later this year.

Uniqlo’s strength is simplicity and applicability. With the jacket type, Uniqlo saved 90 seconds by eliminating unnecessary details. That helped the company save a huge amount of time and money.

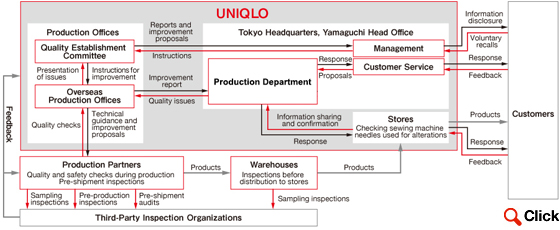

Uniqlo hires a third party to pre-test all materials at the prototyping stage and before mass production to confirm quality and safety. Finally, the finished product is again inspected before leaving the factory.

One disadvantage of outsourcing production is the difficulty of quality control. However, Uniqlo has been overcome by the “Takumi” system. They send about 400 skilled textile artisans to outsourcing factories to share techniques and help maintain quality standards and ensure worker safety.

Logistics

The inventory control department tracks sales and inventory weekly, then dispatches the necessary replenishment rate to fulfill orders. At the end of each season, the selling price will be adjusted again if it is found that the products still have unsold.

If sales of a product drop sharply, Uniqlo may use that material to make another product. For example, if the sale of cashmere sweaters suddenly drops, Uniqlo can turn that goat wool into scarves to sell.

Unlike Zara, which uses a centralized distribution system (all products will be gathered at 4 distribution centers in Turkey), Uniqlo uses a regional distribution system, mainly in Asia, which guarantees transit time is within 6 days (offline sale) and no more than 1 day (online sales).

“Uniqlo is not a fashion company, it is a technology company”. In 2018, Uniqlo supply chain management was changed after 90% of workers at a distribution center in Tokyo replaced by robots. Technology has allowed Uniqlo to reduce the time from ordering to shipping in just 15 minutes, saving up to 95% of time (previously this process took from 8 hours to 16 hours).

In addition, with the mission of enhancing product quality, Uniqlo is ready to recall or cancel all orders in case of detecting errors that seriously affect product quality and consumers’ health.

Market Channel

Instead of following trends, Uniqlo focuses on the philosophy of “making for all”. Its products focus on simplicity, essentials, and popularity with a longer life cycle.

To push sales, the brand has applied a penetration pricing policy, keeping its product prices on par with competitors. Uniqlo always captures a relatively large share of the market with outstanding quality and reasonable prices.

Currently, Uniqlo owns more than 2000 retail stores worldwide, covering Asia, Oceania, Europe, and North America. In particular, the Asian market is the spearhead of this brand.

In addition, Uniqlo is expanding its online-to-offline (O2O) services to combine a physical store and an e-commerce network. Customers can choose to shop online at a UNIQLO store after choosing the product that fits them. This two-way service helps drive sales.

Uniqlo leaders understand that local culture is crucial when entering a new market. Therefore, brands must adapt their communication strategies to suit each region. Uniqlo uses Twitter and Facebook in the UK and US but Renren in China.

Minh Ngo

FURTHER READING

Supply chain management: They key for era of space exploration