HIGHLIGHTS

- Like other famous sport-product companies such as Nike or Adidas, Decathlon mainly outsources the production of main products.

- Decathlon is now incharge of design, production, distribution, and recently supply – one of the key factors for low-cost production.

- The world’s leading sportswear company pursues eco-design with new environmentally friendly designs by extending product life cycles and minimizing waste disposed to the environment.

- Besides using CAR and CAC as intermediate point, products can be directly distributed from the factory to stores in the country where the factory is located.

FULL ARTICLE

Global Manufacturing

Like other famous sport-product companies such as Nike or Adidas, Decathlon’s supply chain mainly outsources the production of main products such as: sportswear, equipment and sports equipment. However, this company still owns 9 self-manufacturing sites to produce some unique items or for researching & product development purposes, these production methods will later be transferred to their manufacturing partners.

According to a representative of Decathlon, its core business strategy is not to build large factories, but to establish partnerships for production expansion in potential markets. Manufacturing is the only stage Decathlon co-operates with subcontractors which are mainly located in Asia, most in China and Vietnam. Decathlon penetrated Vietnam in 1995, until now, there have been more than 100 Decathlon’s partners (subcontracted factories). Among which, there are 39 level-1 manufacturers and the rest are level 2 manufacturers with a total of about 80,000 employees. The entire manufacturing process at these subcontractors, from the import of raw materials to quality assessment is strictly controlled by the contract managers as well as through Decathlon’s Production Offices located in the manufacturing countries or nearby areas (in case there are few factories in one country) in order to prevent possible risks arising. However, the outsourcing trend is possibly changing as Decathlon is trying to achieve vertical integration in the supply chain by acquiring manufacturing plants.

Specialization makes the products the highest quality, therefore, each factory in the Decathlon’s supply chain will only be assigned to produce a certain number of products. For instance, bicycles are manufactured in Spain, Catalans are incharge of product shower caps and socks,etc. The input materials for these factories are strictly managed by Decathlon, the same machines, production lines and fabrics are used in order to synchronize technical norms leading to cost cutting and time-saving.

Forecasting

Sports products’ featured characteristics of relatively stable and not trend-following allow Decathlon to make a forecast 3 years in advance. The forecasting result is the number of products sold, the specific product and design of each product depends on the market volatility.

Sales historical data as well as the opinions of employees at each store are regularly collected and analysed at Decathlon’s headquarters.

Vertical supply chain management

Decathlon is now incharge of design, production, distribution, and recently supply – one of the key factors for low-cost production. Decathlon has developed separate brands for each sport, alongside international brands. The high-quality products developed in-house show Decathlon team’s creativity. Decathlon is the pioneer in the field of 2s-tents or foldable ping pong tables, their private label accounting for about 80% of sales.

Sustainable production

The world’s leading sportswear company pursues eco-design with new environmentally friendly designs by extending product life cycles and minimizing waste disposed to the environment. Decathlon’s supply chain is gradually replacing traditional materials with environmentally friendly ones such as eco-cotton accounting for only 12% of the world’s total cotton production or plastic waste.

By 2019, 95% of Decathlon Vietnam’s total cotton consumption are from sustainable sources:

- During the production process, Decathlon committed to reduce 28-30% waste of raw materials through the use of that material for remanufacturing, ensuring zero-waste to the environment. For example, fabric leftover after cutting and sewing will be reused to make bags for customers.

- The adoption of friendly energy such as wind energy, solar energy reduces Co2 emissions released into the environment. In 2019, 58.9% of Decathlon’s electricity consumption came from renewable energies.

- Decathlon has always been committed to complying with regulations to ensure human rights about standard working conditions (Strict compliance are conducted by its partners).

Quality standards

Decathlon has its own set of quality standards that need to be adhered to by manufacturing plants. Every month, 15 auditors will visit production plans in different countries to check and control compliance with quality standards. A uniform product quality framework will be established by the company and reviewed every period. In addition, Decathlon also ensures legal aspects, ethics, safe working conditions for employees and other environmental aspects. In 2019, the number of quality-related returns was only 1,213 /1,000,000 products sold.

Staff

In 2019, Decathlon had 102,307 employees, only 5% of which perform designing and production tasks. Two main tasks of Decathlon staff in operation fields are to produce products in Decathlon-owned manufacturing sites and to find efficient production methods to transfer to partners.

Global Logistics

Distribution

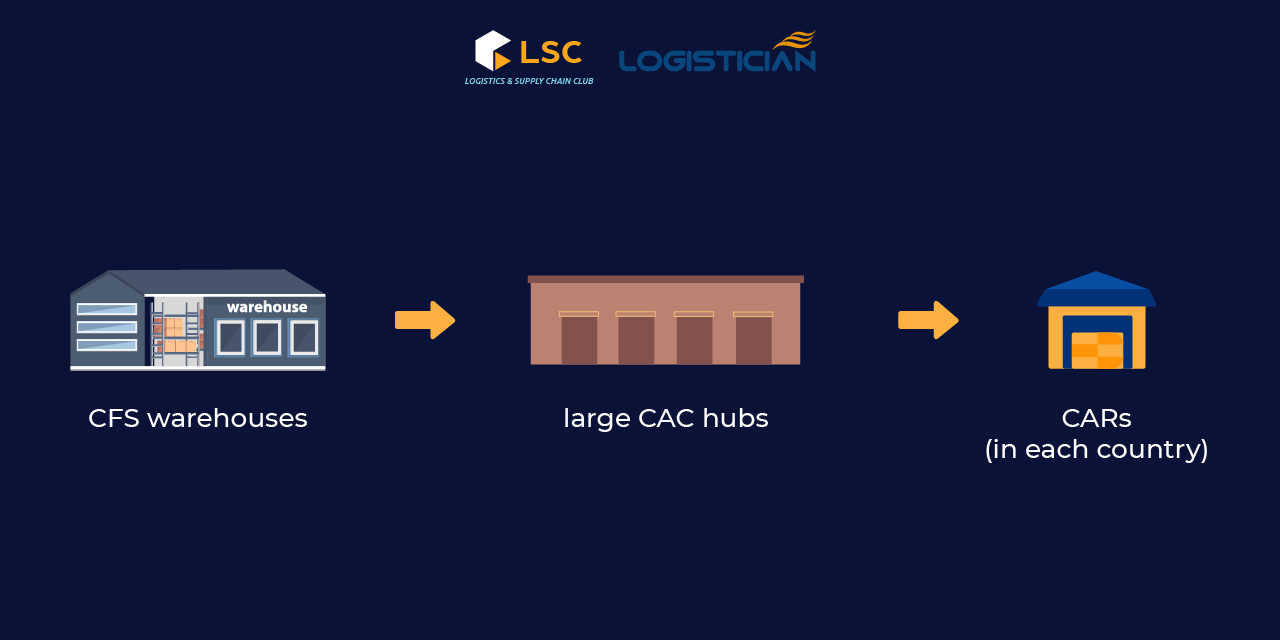

Goods after production are stored at the manufacturing plants for a period of time until the delivery deadline or immediately moved to a CFS warehouse for packaging, ready to be transferred to large CAC hubs (depending on the demand of each item). In CACs, goods are stored in large quantities and products are stored with low inventory turnover. Taking Southeast Asia as an example, goods are stored in Malaysia – Tanjung Pelepas (CAC) (this location was chosen as the CAC due to the balance among cost, lead time, management level and logistics infrastructure) before transferred to CARs (scattered in each country and located near the stores or in the area of the stores to quickly meet customer demand). For example, another CAR at Saint Quentin Fallavier supplies goods to about 50 other stores. In addition, the store in Ecully (France) is supplied goods 1 to 2 times per day and is also bundled with the nearby Limonests store to reduce shipping costs.

With a view to optimizing transportation costs, unlike the supply chain of fast-fashion company Zara (all products after being manufactured will be shipped to the main hub in Spain for quality control and distribution organization), besides using CAR and CAC as intermediate point, products can be directly distributed from the factory to stores in the country where the factory is located (if product demand arises). This distribution network helps reduce cost significantly. Decathlon Vietnam’s products are 80% from CAC Malaysia and 20% directly from manufacturers in Vietnam (this 20% can also be stored in an outsourced warehouse then shipped directly to stores).

This difference in the supply chain model is caused by characteristics of the product line. For Zara and H&M, whose product characteristics are “fast fashion”, products need to keep up with trends. Meanwhile, sports products are not seasonal or have to follow trends. Their product lifecycles are longer than fast fashion products.

Inventory Management

Replenishment mechanism is automated for most products every 10 minutes, calculated based on the data from RFID codes attached to each product. However, with software, factors of seasonal changes such as weather or holidays are not taken into consideration despite their huge impact on sales, especially for seasonal products; therefore, human intervention is needed in the forecasting process. With this replenishment system, product availability is an integer between 95 and 98%. Currently, inventory turnover is around 70%, which means 1 to 2 orders per product per week.

Products that are rarely sold and have a longer shelf life can have stock turnover of about 40 days. In the coming years, one of Decathlon’s goals is to reduce the storage time in the store, while keeping inventory levels the same since inventory cost in CAR is cheaper due to their locations in the suburbs. Decathlon aims to implement a “Just in time – JIT” policy with low inventory. This supply chain allows stores to get any item in less than 48 hours after checkout.

Packaging

Decathlon considers that product packaging does not help sport exercise. Therefore, its packaging designs are simple and have no plastic in order to minimize the impact on the environment.

Cargo handling

There are 3 different areas at Decathlon’s Logistics Center:

- Pick-up area

- Receiving and sending area

- Pallet racking area

The Decathlon Logistics center uses: SKUs to classify goods by size; each product category has an unique code in order to optimize for internal warehouse control; and using standard ABC classification and inventory control.

When there is an order, operation staff will use trolleys to manually load goods by SKU code managed by warehouse management software (WMS) via radio frequency (RFID) equipment. Cargo handling is loaded onto a conveyor belt, with each main conveyor having ten built-in picking tables on both sides. Each table corresponds to a certain number of shelves and operators, which varies according to the number of orders. Once the orders have been sorted, the warehouse staff places the boxes on a central conveyor belt that takes them to the next areas. When the orders have been fulfilled, the conveyor will deliver them directly to the verification and packaging area. The conveyor ends at the Consolidation Area, where completed orders are sorted automatically. At the end of the warehouse handling process, the staff verify the order and seal the package if there is error-free. These separated packages are later combined and distributed in loading pallets to optimize transportation cost.

Transportation

Decathlon partners try to limit the use of aircrafts through an aircraft sharing system. Accordingly, goods with an expected storage time of more than 3 weeks will not be considered “urgent” goods and will not be transported via air.

Railway is considered a greener transport than aviation. In 2017, the use of rail shortened the transit time from Wuhan (China) to France from 3-4 days (originally 26 days). Additionally, the size of train blocks has been reduced to 20 containers (2019) instead of 40 as in 2018.

Sea transport is still the most popular, cheapest and least polluting mode. Ocean shipping accounts for 82.2% of Decathlon’s shipping volume. Decathlon applies a consolidation method for all its partners to a shipping company that is committed to the “Clean Cargo Working Group” program.

Decathlon encourages its employees to use “Green” forms of transportation such as bicycles, public transport, carsharing, etc. To optimize empty trucking, the reverse side of the truck is used to bring the hangers from the store to the warehouse.

Recycling, waste treatment and energy management

Decathlon controls waste from design (minimalist and eco-designs), production, packaging to sales (increasing the product’s 2nd life cycle, recycling hangers, trash).

- RESELL: Launching the “Decathlon Occasion” program, Decathlon buys back used products (in good condition) and for B’twin bikes and skis in select stores. In 2019, 20,000 second-hand products were sold in France.

- REPAIR: 79% hangers (equivalent to 28.4 million) reused hangers (up 238% compared to 2018). With a network of workshops in 26 regions, products can be repaired, spared and even personalized. Moreover, they select easily compatible and readily available parts, so that anyone can repair the product easily. In addition, Decathlon also rents bicycles, climbing tools, etc. to encourage use rather than ownership.

- DONATE: The donation campaign was launched in 2017 with a mission to bring a second life to returned, defective, demo and test products. Stores can donate to local and national organizations.

- WASTE: The implementation of waste treatment at the local level has resulted in the proportion of waste sorted in 2019 at stores at 39% and in warehouses at 63%. Each country will dispose of its waste independently. With its commitment to RE100 in 2018, Decathlon’s goal is to reduce CO2 emissions by using 100% renewable energy by 2026.

Create a global market channel

Decathlon’s analysis of the global market channel will be based on the 4P model of marketing.

Product

Decathlon’s product portfolio includes sports equipment, accessories, apparel, footwear, etc. Decathlon’s product collection is diverse for all sports including football, baseball, basketball, cricket, badminton, archery, billiards, darts, hockey, rollerblading, volleyball and even diving. In addition, there are several Decathlon owned brands such as Artengo, Domyos, Kalenji, New Feel, Inesis, Oxelo.

Price

Decathlon has always strived to promote sports around the world. As a result, all products are available at affordable prices (maintained at around 20% lower than competitors) while they are still maintaining quality.

Place

In 2019, there were a total of 1,647 stores worldwide (an increase of 9% compared to 2018), of which 97 stores and warehouses were certified for environmental friendliness, such as LEED, DGNB, BREEAM. LED technology with eco-design and real-time energy control systems are being used in all new stores.

For online purchases, distribution centers are responsible for shipping and delivery. Due to its efficient logistics and distribution systems, Decathlon was able to maintain its delivery time target of 72 hours.

Promotion

Decathlon promotes itself as an innovative brand with high-quality products. Research and development centers are used to meet the needs of their customers and connect with them. The unique customer experience in-store, where everyone can spend time knowing more about the sport and enjoying their shopping time, is what differentiates Decathlon sales.

For Decathlon, customer satisfaction is a top priority. Therefore, all Decathlon products come with a warranty of at least 2 years and even a lifetime warranty.

At the end of each season, Decathlon always has attractive promotions up to 75% for products. In addition, Decathlon also has gift programs and shopping vouchers on special occasions.

Nhat Huyen