HIGHLIGHTS

- The prolonged container ship crisis at US ports posed some problems in building a sustainable global supply chain.

- America started some projects to limit the foreign dependency, firstly constructing semiconductor production in this country.

- Also, coordination and forecast were important factors which ensured an agile supply chain.

FULL ARTICLE

The long-lasting crisis

The US East and West coasts had suffered from container ship congestion for months. Ships from China and other Asian ports were lined up 40 miles, waiting to dock offshore the West Coast.

According to eeSea, there were more than 60 container ships stuck offshore for nearly 3 months, at Los Angeles and Long Beach ports areas specifically. On average, each ship currently held 14,000 containers, equivalent to 100,000 USD. It was not just the West Coast that was affected, but also the east coast of New York and Georgia.

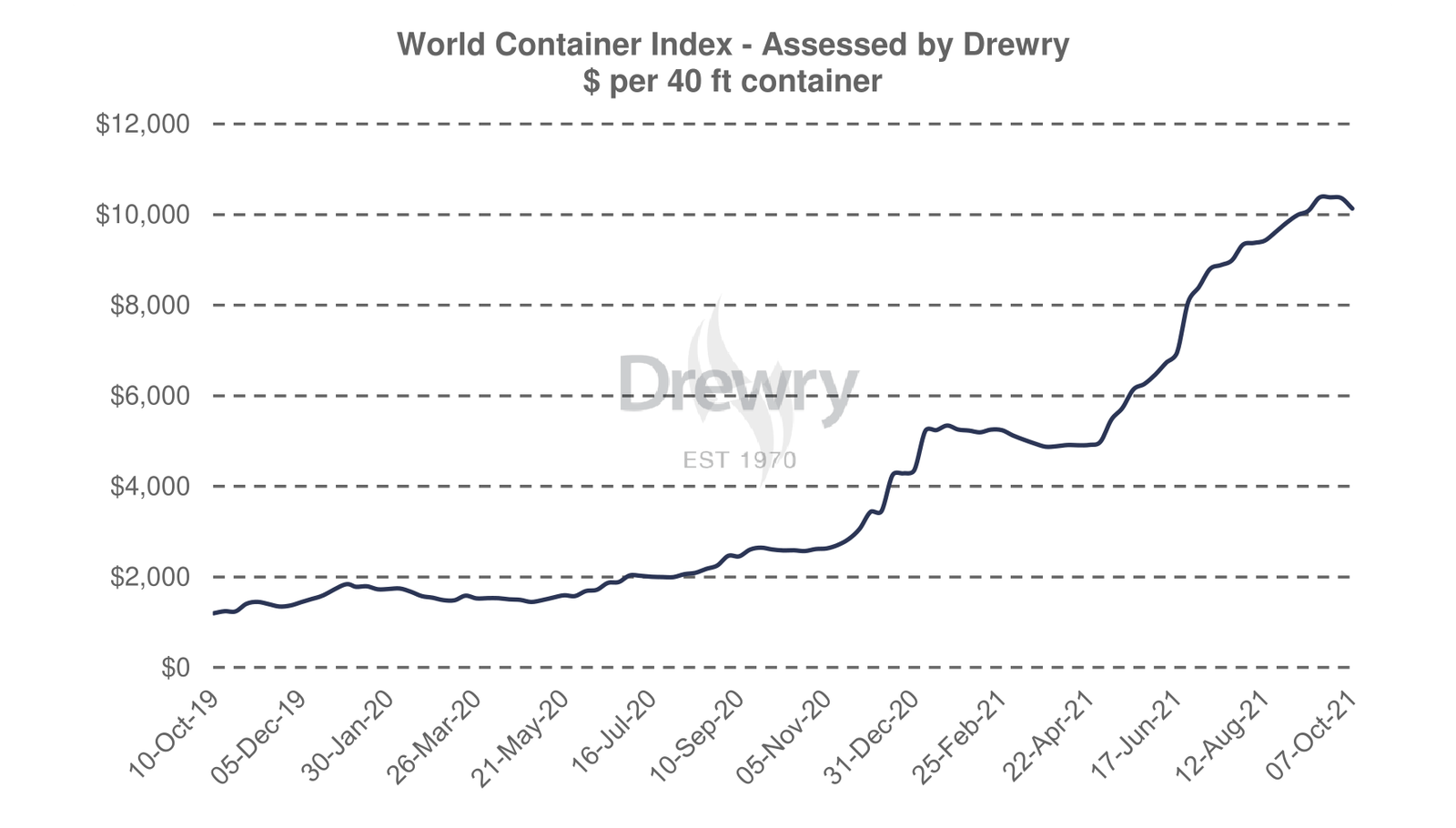

According to the World Container Index of Drewry – a leading maritime research and consulting firm, freight rates from Shanghai to Los Angeles fell 8% (or 999 USD) to 11,173 USD. Meanwhile, the freight rate from Shanghai to New York decreased by 739 USD (equivalent to 5%) to 15,110 USD per one 40 feet container. Freight to the US has gone down, however, post-pandemic problems are still an obstacle to the circulation of goods throughout the supply chain.

Challenges to overcome

The Container ship crisis in the US, along with the recent congestion problems at Asian posts, were signs of an unsustainable supply chain that has not been able to recover immediately.

Demand increasing but could not be met

The ending of social distance measures caused production and consumption demand to bounce back gradually. However, the global supply chain is struggling to meet highly growing demand, especially in the US market.

The volume of goods imported from Asia into the US in August 2021 increased by an average of 26% per week, equivalent to 44% – 60% over the same period in 2020, in order to meet the consumption demand in this market.

Meanwhile, the loading capacity and infrastructure of ports were still limited and could not handle the large number of container ships flock to, which led to serious congestion at sea.

“The Covid-19 pandemic has highlighted that ports are in desperate need of investment. The entire port infrastructure system has been overwhelmed for the past year.” said John Manners-Bell, chief executive at consultancy Transport Intelligence.

Too much foreign dependency

The recent shortage of semiconductors showed the risks of world manufacturing concentration in a few places, mainly in Taiwan, China and South Korea. Furthermore, the need for chips and semiconductors in the US was huge.

However, the disruption of transportation routes to the US due to the closure of some Asian ports also caused ship congestion at some American ports. That also forced some factories in this country to shut down. Currently, the US has been constructing some own semiconductor factories to limit its dependence on foreign suppliers.

Requirements for good coordination and forecast

The closure of major ports in Asia also made the cargo traffic uneven – huge difference during and after the port’s shutdown. Plus the sudden demand increase in the US had caused an overload in the number of container ships from Asia to the US. That problem perhaps led to huge avenue losses to the country. This posed a requirement for the ability to coordinate and forecast demand to store an appropriate level of goods which could meet the demand.

Thanh Thảo

FURTHER READING

Explained | How bad is the world’s energy crisis?