TOPLINE Toyota is Japan’s leading automobile manufacturer, with a history of nearly 100 years, Toyota is continuing to assert its position in terms of quality, price and ability to meet customers’ needs. So what is the secret to Toyota’s success? That is the lean production system model and Just-in-time is the key.

KEY POINT

- Just-in-time (JIT) is an inventory management strategy that aims at “no inventory, no waiting time, no additional costs” during operation and production.

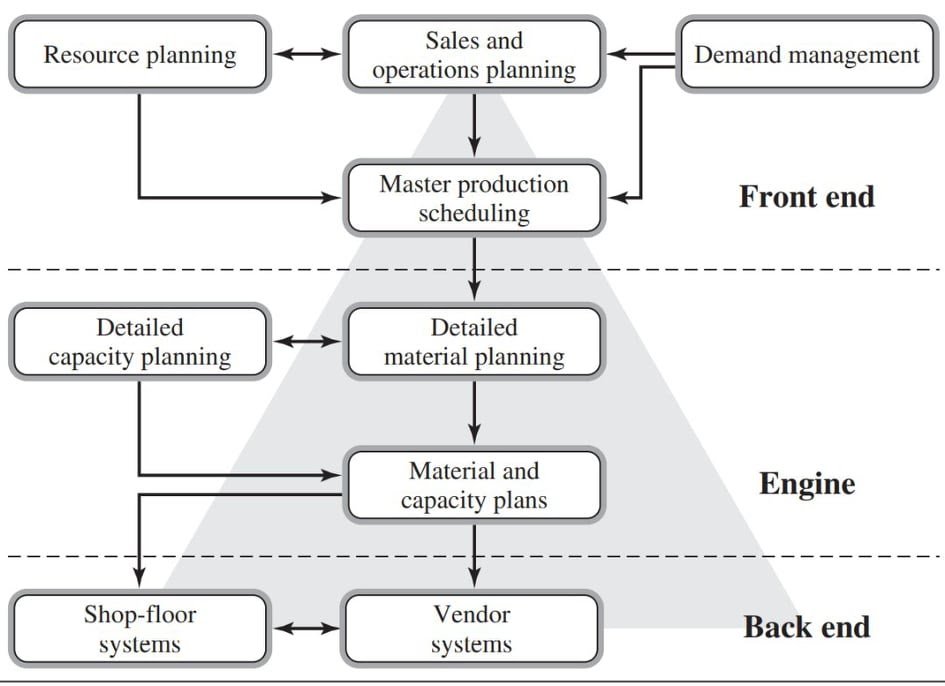

- JIT affects all three areas of the production planning and control system, including the front end, engine, and back end.

- The success of JIT is ensured by four basic elements: product design, process design, human/organizational factors, production planning and control.

ARTICLE

What is just-in-time?

Just-in-time (JIT) is an inventory management strategy whose primary goal is to adjust the flow of materials in line with production schedules and customer orders. JIT is implemented to ensure the production of “the right product, in the right quantity, in the right place, at the right time” with the goal of “no inventory, no waiting time, no additional costs”.

Fact: JIT was first applied by Toyota in 1970 and it is considered the key to their success.

The benefits of using the Just-in-time (JIT)

- Reduced production time (the amount of time it takes for a product to be converted from raw materials to finished products) as JIT has minimized waiting times between stages in the process.

- Reduce the number and cost of transactions: when applying the JIT strategy, businesses almost have to maintain everything right and just right, thereby minimizing the amount of returned goods, and always keeping the inventory warehouse to a minimum, thereby reducing costs such as transportation costs, warehousing costs, bookkeeping costs, etc.

- Simplified MPC systems: JIT’s goal is to keep things “right”, so businesses tend to simplify all operational processes, making it easier to use this strategy as much as possible.

- Better meet the needs of the market: starting from the feature that all operating processes are simplified, businesses can easily change to better adapt to the needs of customers.

- Reduce inventory, save warehouse space: with JIT, production will have to be done at the right time, in the right quantity, in the right place, so there is no need for inventory, saving space, and storage costs.

- Workers are involved in product improvement: for businesses using JIT, they always think that workers are directly in contact with products, so their feedback is very necessary to improve. production quality. Therefore, they always encourage workers to be deeply involved in the product development process.

However, JIT is not always a strategy that guarantees the success of businesses that adopt it. If JIT brings tremendous success to Toyota, it also causes this business to suffer.

The prime example is Toyota, which in February 1997, after a fire at Japanese-owned automotive parts supplier Aisin decimated its capacity to produce P-valves for Toyota’s vehicles. Because Aisin is the sole supplier of this part, its weeks-long shutdown caused Toyota to halt production for several days. This caused a ripple effect, where other Toyota parts suppliers likewise had to temporarily shut down because the automaker had no need for their parts during that time period. Consequently, this fire cost Toyota 160 billion yen in revenue.

How does JIT impact a company’s production planning and control (MPC)?

Manufacturing Planning and Control (MPC) is an enterprise’s production planning and control system. Planning ensures that the goods produced can meet all the needs of the customer. At the same time, control is responsible for ensuring that the process always goes according to plan, or adjusts to changes in the environment.

JIT affects all three areas in MPC including front end, engine and back end. Where the gray area of the MPC will be most affected by the JIT implementation:

Back end

JIT provides greatly streamlined execution on the shop floor and in purchasing. Some reporting systems (e.g. detailed store inventory reports, end-of-year balance sheets, etc.) will be eliminated or restricted, thereby reducing costs, time, and volume jobs for employees.

*Shop-floor: production area or workshop (including equipment, warehouses and storage areas, …) where assembly or manufacturing is carried out, either by automated systems or by tools to multiply or combine the two.

Engine

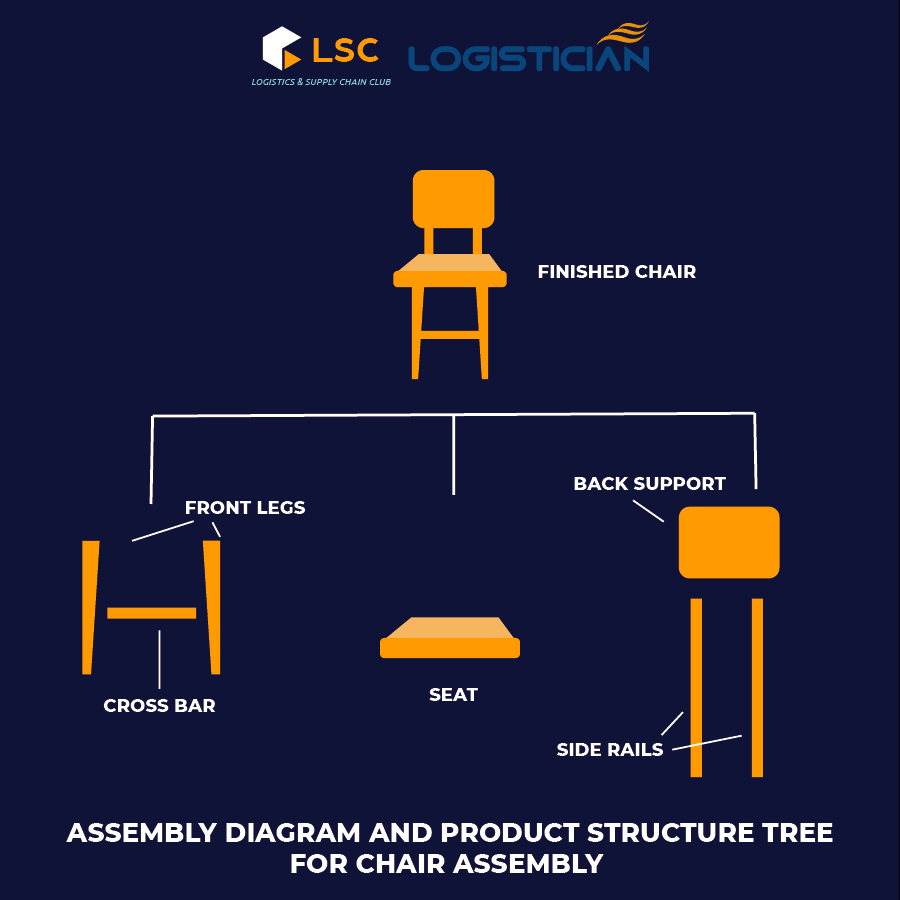

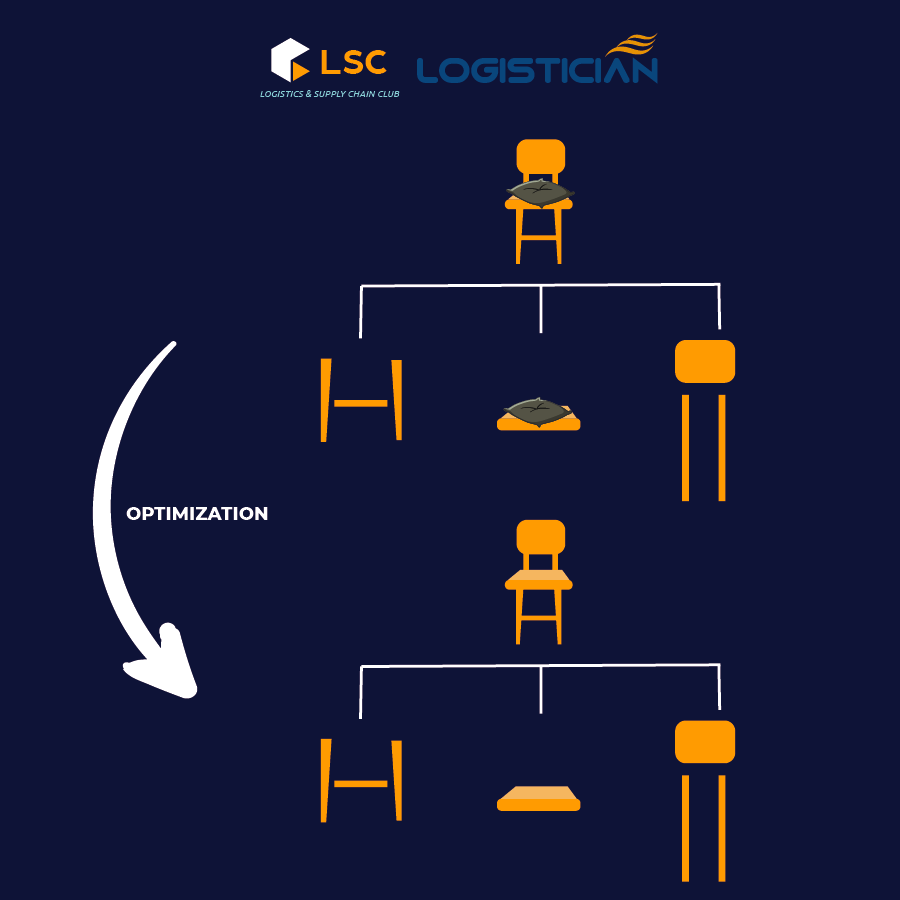

To ensure simplicity and accuracy, the JIT strategy will try to optimize the structure of the product (shown in the Bill of material BOM** diagram) while ensuring quality.

As a result, the complexity of production planning is reduced, significantly reducing the lead time to the finished product.

Example

When manufacturing a chair, a business needs to use wood and soft plastic (as a backrest). However, to optimize, they switched to all-wood for all parts. This simplifies the procurement and production process, shortens the time, and focuses on the assembly to create the finished product.

Or, instead of doing the whole process of cutting and sawing wood, the business will outsource that step and thus reduce the production process by 1 step, saving time and labor, simplifying the transportation process.

**BOM: Bill of Material – A bill of materials is a list that includes materials, assemblies, parts, and components, as well as the quantities of each material needed to manufacture a product.

Front end

The JIT strategy will significantly reduce the lead time of the stages in the production process. Many make-to-stock (MTS) businesses are now being referred to as make-to-order (MTO) or assemble-to-order (ATO) businesses. This is because they can minimize the time it takes for the product to get to the customer, so to ensure that they always produce the right amount, they may decide to only produce after receiving the order ( MTO form).

4 core factors to ensure the success of JIT (4 pillars)

There are many factors to successful JIT adoption. However, in most cases, the following four basic elements are considered to be the pillars of this strategy: product design, process design, people/organizational factors, Manufacturing Planning and Control.

Product Design

This includes quality (ensures products are not damaged and returned), design for manufacturing cells, and optimization of levels in the BOM.

Each BOM has different levels, with the top level being finished products and lower levels consisting of individual semi-finished products and materials.

Example

Since each level in a bill of material represents a stock point, reducing the number can significantly reduce inventory requirements and speed processing.

Process design

The optimization of levels in the BOM and the process design activity are closely related.

Because the product must be made simpler, the production process also follows, which can reduce many stages. This both shortens production time and makes the process easier to control and operate.

Human/organizational elements

To ensure JIT implementation, people are an important factor that cannot be ignored. JIT requires businesses to constantly change and improve. Therefore, their employees also need to learn regularly to improve worker performance. In particular, JIT focuses on work and is cross-trained**** to create employees with diverse expertise.

Cross-trained employees can handle a variety of jobs, combined with a simplified process, so you can reduce the number of employees while still ensuring the quantity and quality of production product as before.

****Cross-training: Cross-training is the training of workers/workers/employees in different roles or training them to do jobs outside of their main job.

Manufacturing Planning and Control (MPC)

In the context of a manufacturing enterprise, it is always necessary to plan production (from the total to the details) and control them. Production plans are made based on many inputs, including BOM. Since the product structure has been optimized to reduce the number of steps and time as much as possible, planning (detailed materials or assembly) will be greatly simplified. From there, the control process will also be easier.

Just-in-time’s Applications

The JIT model can solve most of the inventory elimination problem and this is an outcome that many businesses are aiming for. One of the practical ways to implement this JIT strategy is Vendor Managed Inventory (VMI). This is also the method that has contributed greatly to the success of one of the largest grocery chains in the world: Walmart.

With the VMI method, the supplier will have access to the data about the goods in the manufacturer’s inventory (in Walmart’s case, the number of goods in the store) and automatically replenish when the stock is low. This helps to reduce purchases, reduce time and inventory because suppliers will quickly replenish when needed without having to stock too much. A necessary condition for applying this method is that the delivery time of goods must be relatively short.

Hong Dao

FURTHER MORE

Need to reconsider the practicality when using, so is the EOQ model still relevant?