HIGHLIGHTS

- Onshore refers to the production of a product right at the consumer market.

- Nearshore refers to produce in countries that are close to the consumer market and often have similar time zones, or minimal differences.

- Offshore refers to manufacturing products in remote countries with significant time zone differences.

- The responsive onshore sources should focus on high-value products with high demand volatility, while the low-cost, offshore sources should focus on lower-value, high-volume products with high labour content.

FULL ARTICLE

Onshore

Onshore refers to the production of a product right at the consumer market. For example, a business in California would choose to outsource their partners in New Jersey, which are two different states in the same country.

The advantage of this type is that the business and the outsourcing partners come from the same culture and speak the same language. In particular, face-to-face meetings or training can be conducted more easily, saving time.

However, the biggest problem with the Onshore model is that it is much more costly than Nearshore or Offshore when enterprises do the same job. According to Glassdoor, a website that allows free job postings, as well as employer reviews in the US, the average salary of American R&D staff in 2020, is about 95 thousand USD, while the salary is the average of R&D staff in Norway is about 607 thousand NOK (equivalent to 74,000 USD). In addition, the model range is often narrower because the number of talent is limited.

Nearshore

Nearshore refers to produce in countries that are close to the consumer market and often have similar time zones, or minimal differences. For the US, the best options are Canada, Mexico, or Latin America.

This solution is considered by many as a win-win. In fact, enterprises can still save on labour costs compared to the Onshore model and they also don’t have to worry about working in different time zones. In addition, enterprises can still ensure efficient and convenient control of the development process. However, some language and cultural differences may still occur.

Offshore

Offshore refers to manufacturing products in remote countries with significant time zone differences. Normally, for the US, this applies to countries like India, China, or Ukraine.

Some of the potential benefits can be mentioned as unrestricted access to global talent, hiring a team of experts at a lower cost than the other two models.

On the contrary, there are a number of risks businesses need to be aware of when implementing the Offshore model, including the significant time zone or cultural differences. Especially, due to the geographical distance, it is more difficult to train, manage and control the partner’s activities. To overcome this problem, some businesses carefully plan the work schedules of the permanent team and the outsourced team, so that the work on the projects goes smoothly.

What is the best choice?

As can be seen, most companies need to tailor their supplier portfolios based on a variety of product and market characteristics. For example, Zara uses sourcing outside of Europe to produce trendy and responsive products. In contrast, basic items like white t-shirts are sourced from lower-cost establishments in Asia. As with Zara, an optimal choice consists of a combination of fast-response and low-cost suppliers.

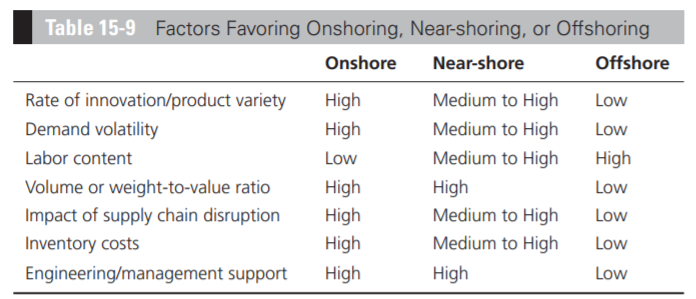

To use the right portfolio effectively, demand needs to be distributed among the suppliers, in accordance with their capabilities. The table below shows the factors that influence the choice of a sourcing source capable of meeting demand quickly or sourcing at a low cost.

In general, if businesses want to find sourcing that can respond to demand quickly, they will tend to adopt the Onshore or Nearshore model. On the contrary, if the enterprise’s goal is a low-cost strategy, then often the enterprise will choose the Offshore or Nearshore model.

The responsive onshore sources should focus on high-value products with high demand volatility, while the low-cost, offshore sources should focus on lower-value, high-volume products with high labour content.

China and other parts of Asia were popular offshore sources for the two decades between 1990 and 2010. Some trends currently in place, however, are making American managers rethink their offshoring choices. One is the change in Chinese wages and the strengthening yuan, both of which diminish the labour cost advantage of China, especially when compared to near-shore locations such as Mexico. In addition, the increase in oil prices and transportation costs like a tariff barrier, making offshoring somewhat less attractive. Finally, the increase in volatility from the US-China trade war and the need to mitigate risks have also encouraged supply chain designers to include an onshore or near-shore source to complement a low-cost offshore source.

Minh Ngo