HIGHLIGHTS

- A prominent feature of Decathlon’s global procurement strategy, and also relatively common among leading multinational corporations (MNCs), is sustainable development trend.

- Decathlon owns 42 manufacturing offices in 24 countries and also works with suppliers in 23 other countries.

FULL ARTICLE

Decathlon’s milestone

Decathlon first appeared on the market in 1976 in Lille (France) with a retail chain as well as a series of exclusive sportswear brands. Only after a decade, Decathlon expanded to Germany in 1986, Spain in 1992, China in 2003, India in 2009, etc, and in April 2019 Decathlon had its first store in Hanoi (Vietnam).

In 2008, Decathlon defeated its competitors (based on 3 criteria: profit margin, market share and revenue) to become the leading retail chain in France and ranked 3rd globally. Decathlon is famous for its slogan “Sports for all and All for sports”.

Decathlon’s Products

Decathlon specializes in providing sports products, although having seasonal characteristics owing to the sports played change with the seasons, the designs of the products are not required to change continuously, regularly or follow trends as famous fast-fashion brands like Zara or H&M. This leads to Decathlon’s longer product life cycle compared to conventional fast-fashion products. Its products vary, including:

- Sport clothes and shoes

- Sports accessories (backpacks, hats, sunglasses, etc)

- Sports equipment (bicycles, weights, water bottles, camping set, etc)

Decathlon’s relatively reasonable prices meet the demand of customers from different walks of life, the prices ranging from thousands to millions VND.

Decathlon Supply Chain Overview

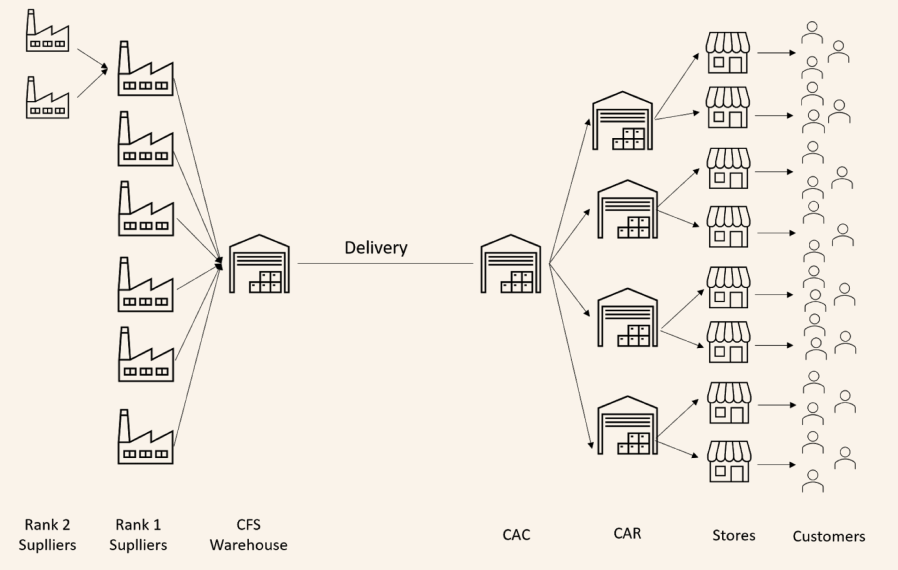

Note:

- CFS – Container Freight Station

- CAR – Regional Warehouse

- CAC – Continental Warehouse

The upstream of Decathlon’s supply chain include raw material suppliers (Tier 2 or tier 3 suppliers, depending on the product type), these suppliers will provide raw materials for Tier 1 suppliers (known as finished-product-manufacturers). Finished products later will be gathered from Tier 1 suppliers to CFS warehouses, then internationally delivered to continental warehouses (CACs) for storage, sorting and quality assessment before transferred to regional warehouses (CAR). Products are finally distributed to each store for selling.

In this insight, only the first stage of Decathlon’s global supply chain: Global Procurement is covered, other activities such as production, logistics or marketing, etc. will be mentioned in the following articles of the series.

Market Demand

Before conducting a sales and operation plan (S&OP) or later, a raw material requirement plan (MRP), Decathlon carries out market demand research based on culture, customs, and geographical features, etc of different countries. Owing to that, Decathlon can determine which products are suitable for each market, all market research data will be aggregated at Decathlon’s headquarters for carrying out master materials plan, before distributing production requirements to each individual supplier of Decathlon.

Global procurement plays such an important role for Decathlon due to its outsourcing strategy. This French company hardly owns any factories and most of its products are manufactured by its suppliers. Vietnam is known to be the country of a relatively large number of Decathlon suppliers, mainly producing clothing – accounting for 50% of the total number of products supplied by Vietnam, followed by footwear – accounting for 36%.

Sustainable supply

A prominent feature of Decathlon’s global procurement strategy, and also relatively common among leading multinational corporations (MNCs), is sustainable development trend. Decathlon implements certain policies to ensure the supply of materials and sustainable products. For instance, 76% of cotton supply and 17.2% of polyester supply originate from sustainable sources, 53.8% of engineers are trained to assess the environmental impact of products and be certified for sustainable production materials supply. Decathlon’s direct suppliers are required to verify compliance with the originating materials in their supply chain against the restricted substances list, social regulatory requirements and guidelines (86% of suppliers commit to chemical disposal by signing Decathlon’s restricted substances list). Decathlon’s production teams in each country maintain relationships with suppliers with high-standards in terms of sustainability development, quality and continuous improvement. This company integrates sustainability training for purchasing staff such as training on measuring CO2 emissions and raising awareness on labor issues for employees.

Define and maintain relationships with suppliers

There are 2 types of suppliers:

- Partner suppliers for each project.

- Long-term suppliers with long-term partnerships, who either have proprietary technology or stand high chances of manufacturing for Decathlon in large quantities. These suppliers are Decathlon’s strategic alliances.

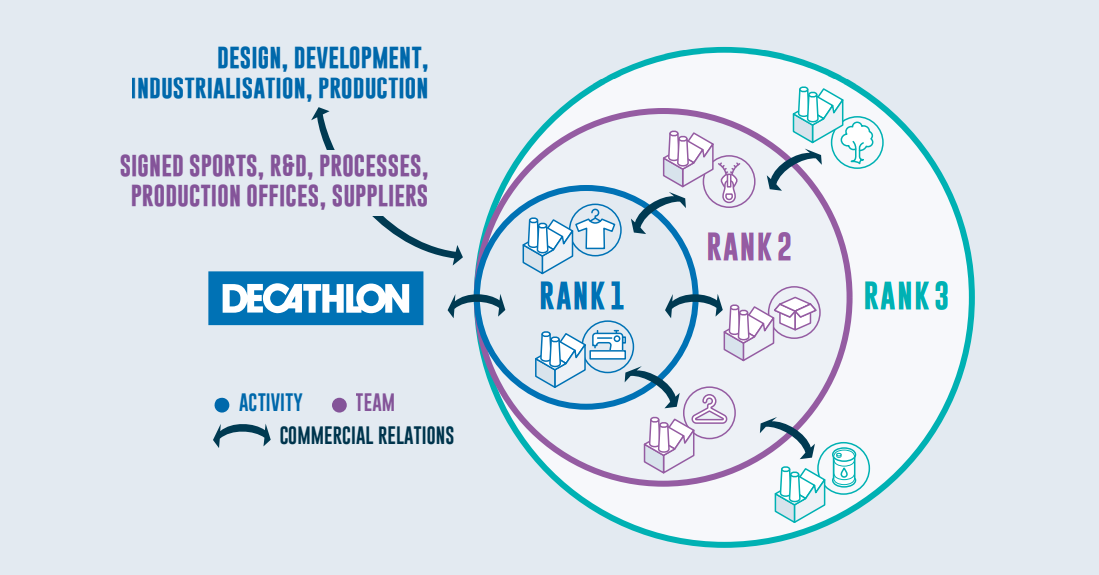

Decathlon controls their suppliers of all tiers divided into different segments:

- Tier 1 suppliers are those who have direct contract with Decathlon. These can be finished-products suppliers or WIP (work-in-process) products suppliers cooperate with Decathlon through contracts of manufacturing, or raw materials supply or (in 2019 there were 1007 tier 1 suppliers, 2.3% lower than 2018).

- Tier 2 suppliers are those who have a commercial relationship with tier 1 suppliers. Decathlon reserves the right to interfere in the selection or evaluation of tier 2 suppliers. However, Decathlon does not interfere with the commercial relationship, trade and legal issues between suppliers 1 and 2 (in 2019 there were 346 tier 2 suppliers, 9% larger than 2018).

Before initiating relationships with suppliers, the company ensures that the supplier’s factory and manufacturing process meets their basic social requirements.

- Suppliers must commit to Decathlon’s Code of Conduct – which establishes safety and human rights requirements in many respects such as child labor, working hours and discrimination ( ensure social responsibility). If suppliers have any violation of these terms, Decathlon will immediately stop contracting with them.

- In the manufacturing and sourcing agreement, the supplier must commit to manufacturing only in the declared and verified locations and territories. Any undeclared subcontracting is strictly prohibited (manufacturing site must be declared and verified with Decathlon).

Supplier evaluation process

Decathlon conducts assessment from the partnership establishment, and regularly evaluates throughout the partnership. These assessments are carried out by the company’s internal audit (trained according to SA 8000) or by external audit parties. The assessment frequency is based on the country’s level of risk. Although the frequency of assessment is different among countries, the assessment criteria is the same for all. During each assessment, the inspector ensures that the supplier is in compliance with local laws. If Decathlon’s requirements are more demanding, the company also ensures compliance with those requirements. Any nonconformities detected are reported to the local Decathlon teammates, who develop action plans with suppliers and ensure effective implementation.

A rating system on a scale from A to E is implemented for assessment (A is exemplary, E is unacceptable). If a supplier is rated E, the suppliers are required to:

- Take immediate action to eliminate the risk covered within a day.

- Analyze the problem to determine root cause and propose a sustainable solution. This action plan will be approved by an internal inspector no later than 3 months after the audit. If the situation cannot be resolved within a day, Decathlon will stop contracting with suppliers immediately.

- Historical data, tracking of assessments as well as action plans are recorded in an internal vendor database that is accessible by all stakeholders.

Purchasing monitoring with Decathlon teammates

Decathlon owns 42 manufacturing offices in 24 countries and also works with suppliers in 23 other countries. Decathlon’s team will work with manufacturers in the countries they have offices and nearby manufacturers (located in the same area) if there are no manufacturing offices in that country.

To strengthen the position of a famous global brand, ensure the product’s high-quality and reasonable cost as well as maintain the company’s profits while still fulfilling the goal of sustainable supply, Decathlon has established and implemented several policies, requiring the efforts, creativity and hard-work of the whole organisation.

However, is the management and coordination of the massive supplier network the only factor that makes the entire Decathlon supply chain successful? What makes Decathlon’s production and logistics activities special? Let’s address these questions with the Logistician in the next articles in the series.

Nhat Huyen