HIGHLIGHTS

- The Track & Trace system automates the process of collecting and recording important information about goods through tracking and tracing their origin and status.

- The Track & Trace solutions market is valued at approximately 2,056 million USD in 2020 and is expected to reach 4,338.5 million USD by 2026, achieving a compound annual growth rate of 13.1%

- With the pandemic accelerating the process of digitization, the use of RFID technology in healthcare has been accelerated in 2020.

FURTHER READING

What do you know about Track & Trace?

Track is the act of tracking the movement of a shipment, while trace refers to tracking that migration. The Track & Trace system automates the process of collecting and recording important information about goods through tracking and tracing their origin and status.

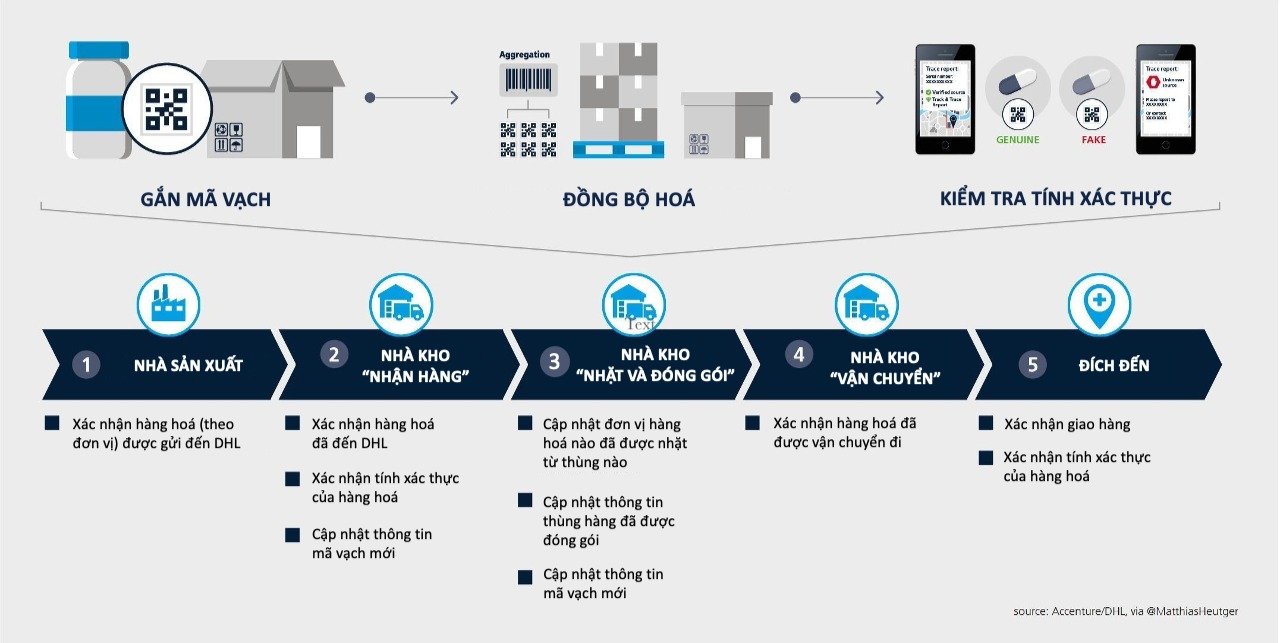

By applying Track & Trace in production, each tracking object (raw material or finished product) will be assigned a separate barcode and stored in the database every time it passes a stage, such as packing, closing the pallet.

In addition, Track & Trace is also applied during distribution and transportation. During the process of the product being transported to the final delivery point, shipment information including packaging characteristics, delivery point location, delivery time, etc. will be sent to the system database.

Benefits of Track & Trace

Input material flow management

Each item is individually bar-coded, which makes it more complete gathering information about the availability of resources, allowing for a smooth workflow. Accurately grasping the quantity, location, and condition of raw materials limits unexpected situations from disrupting the production line.

In addition, the input Track & Trace application helps to prevent counterfeit or poor quality goods because it can quickly trace the origin of the package. This will save time and costs warehousing.

Real-time cargo query

By scanning barcodes and QR codes at each point of goods, this system can provide a lot of information, such as container/package location, bill of lading number, customer information, order number, quantity of goods, weight quantity, status and delivery date, shipping fee, etc.

Managers can quickly detect delayed, lost or damaged shipments, missing assets in transit, etc, ensuring that shipments are delivered on schedule, with the right quality.

Optimizing the quality of logistics activities & Inventory management

Warehouse staff can scan the barcode, retrieve the parameters and the origin of the shipment, which prevent defective or counterfeit shipments before putting them into the warehouse.

Besides, logistics managers easily control the volume of goods and the location of each item, optimizing storage space. It also reduces the time to find goods and the cost of inventory.

Managers can also capture changing trends of customer demand, improving the accuracy of forecasts and optimizing production schedules of enterprises.

Improve customer experience

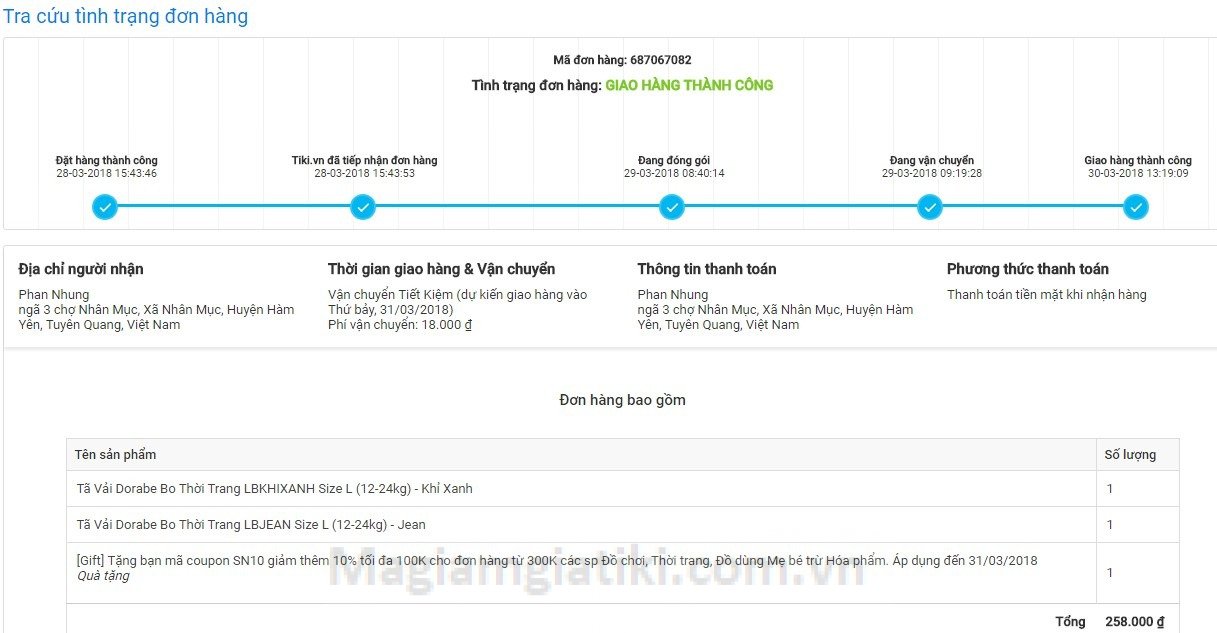

To win customers’ trust, besides meeting good product quality, delivery service is also a factor that needs to be focused on. For example, customers, who buy a book on Tiki, can track the status of the order as packaging, shipping route, shipper’s information, etc. This makes consumers more secure about online purchases and also helps suppliers to monitor and promptly handle unexpected situations that may occur.

This system also helps businesses reduce the workload of the support department, not only vehicle owners but also manufacturers and retailers can track the entire supply chain activity. If there is an incident, they can promptly respond, ensuring the transportation process goes smoothly.

The future of Track & Trace

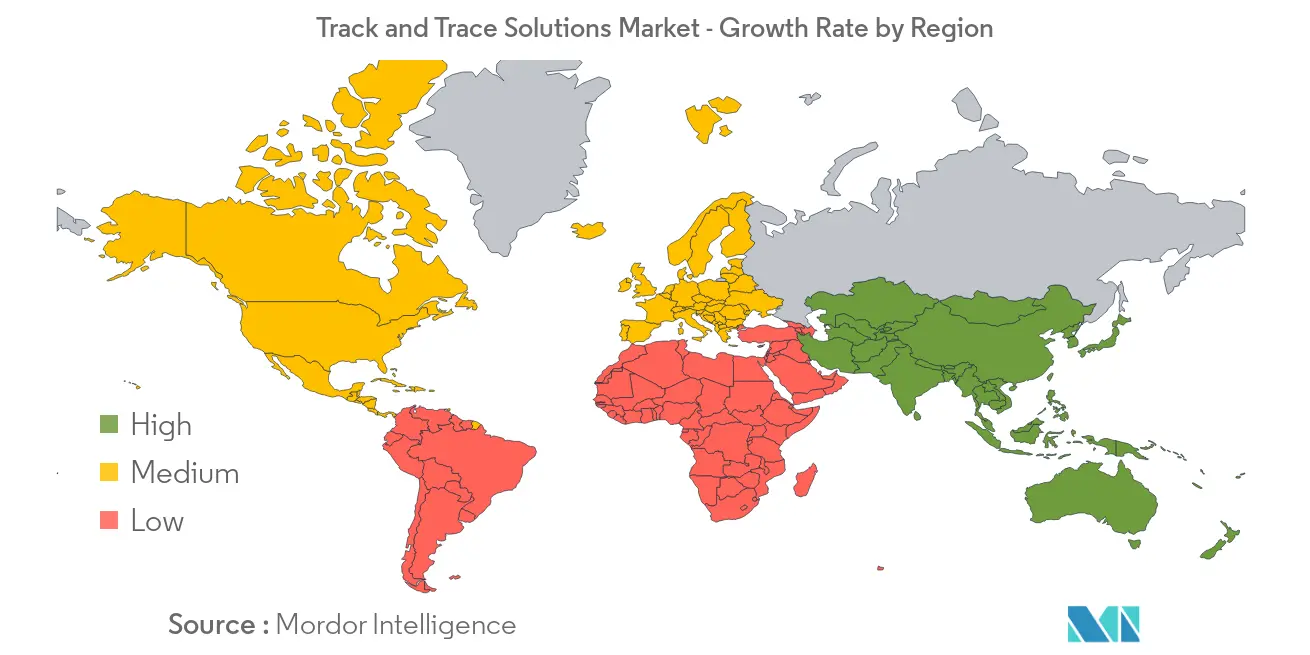

According to a Mordor Intelligence report, the Track & Trace solutions market is valued at approximately 2,056 million USD in 2020 and is expected to reach 4,338.5 million USD by 2026, achieving a compound annual growth rate of 13.1% over the forecast period. In particular, Asia and Oceania are forecasted to be the two largest growth rates regions. Next, the two regions with average growth rates are the Americas and Europe. Also according to the forecast, the lowest growth rate belongs to the African market.

The application of Track & Trace technology in the Pharmaceutical or Medical Supplies industry is no longer strange to suppliers and customers. Counterfeiting is one of the major problems in large-scale pharmaceutical and biopharmaceutical companies. According to the World Health Organization (WHO), counterfeit drugs account for 50% of the pharmaceutical market in the US.

With the pandemic accelerating the process of digitization, the use of RFID technology in healthcare has been accelerated in 2020. They are applied to tracking and authenticating vaccines and diagnostic kits. In June 2020, the United States Department of Health and Human Services, Department of Defence, and ApiJect Systems America have gone under partnership for projects ”Project Jumpstart” and “RAPID USA,” for expanding syringe production and RFID technology could be affixed in these syringes. In September 2020, Fresenius Kabi incorporated RFID-tag-equipped labels on medications such as prefilled syringes and vials which are commonly used in operating rooms in order to enhance the workflow of inventory management.

With the application of RFID technology in the Track & Trace market, organizations can quickly locate items that have been barcoded and stored in a database. Instead of recalling the entire shipment, they simply retrieve the defective products and recall them. This reduces cost losses, as well as making recalls faster and more efficient.

Thanh Thao