HIGHLIGHTS

- Procurement includes all related activities needed to bring goods, services, and any other materials from suppliers into an organization.

- An effective procurement strategy will ensure low costs and competitive advantages of enterprises, which is the link between supply chains.

- Apple implements procurement management well through establishing and developing relationships with more than 200 key suppliers (mostly in China), accounting for 97% of Apple’s supply chain and nearly 600 sub-suppliers (the remaining 3%)

FULL ARTICLE

The simple common formula: Profit = Revenue – Cost.

Apple has sold products which are low-cost manufactured with high prices. People often talk about superior technology, innovative pioneering, or brilliant business strategy of Apple, etc. but in this article, let’s investigate this success from another side – the Apple supply chain, and even deeper: Procurement.

Procurement – the starting point of the supply chain

With every supply chain, whether traditional or complex, the supplier is always the starting point. Therefore, procurement can be considered as the origin of everything.

Conceptually, procurement is a process that includes all related activities needed to bring goods, services and any other materials from suppliers into an organization.

For example, to make the iPhone 12, Apple needed microprocessors and semiconductors, and they bought them from Samsung. Samsung becomes Apple’s supplier.

The eternal question: Are Procurement and Purchasing the same thing?

The concept of procurement is often confused with another term: “Purchasing” because they both refer to the buying of input materials. However, procurement has a broader meaning, encompassing a wider range of activities, and purchasing is one of the activities of it. Procurement is associated with the development and management of supplier relationships, strategic relationships, not just buying and selling. Procurement activities can be widely varied depending on the characteristics of the supply chain and the acquired items.

Why Procurement?

This chain of activity should be given such importance, because of these 3 main roles can outlined below:

- It is considered an essential link between organizations in the supply chain, providing a mechanism to coordinate the flow of materials between customers and suppliers.

- In addition, procurement raises many costs for businesses, and well-handling of this activity helps reduce total costs. For a typical manufacturer, 60% of their spending goes to materials, with companies like General Motors (GM) spending more than $50 billion a year.

- Finally if there is a fault in these activities, raw materials don’t arrive, or wrong materials are delivered, wrong quantity, wrong time, poor quality, overpriced, low customer service, etc will affect product quality and customer service. In today’s fierce competition, no enterprise wants their customers to leave.

With the trend of specialization and globalization, sourcing activities are increasing in supply chains, as companies tend to focus on their core activities and outsource the others.

Now let’s go back to Apple to figure out the issue that was raised in the beginning.

Apple’s procurement strategy – Success doesn’t just come from reputation

Apple owns a global supply chain. Detail parts & components come from all over the world, from rare-earth in China, Japanese labs, American chips, to “big” manufacturing plants in China and then run to Apple Stores, offline and online.

As aforementioned, procurement includes not only purchasing but also the process of finding, partnering, and maintaining relationships with suppliers. Looking at the parts and components that make up an iPhone or Macbook, it can be easily seen that the number of Apple suppliers is “not that small”.

In terms of the number of suppliers, Apple’s network of suppliers can reach 800, spread across 30 different countries. In particular, there are key players such as: Foxconn, Luxshare, Petragon, Qualcomm, LG or even its rival – Samsung. However, there is a paradox that 97% of Apple’s supply chain (including purchasing, manufacturing and assembly) is held by 200 key partners, which means that the remaining nearly 600 suppliers only get 3% of the “Apple pie”, creating a huge competitive pressure.

But Apple is like a “golden gate” that every supplier wants to open, a “golden ticket” for suppliers to become the best suppliers in the world, because of Apple’s reputation for its high-quality standards and strictness with suppliers through their Code of Conduct. To ensure supplier quality, Apple takes the following actions:

- Code of Conducts Assessment includes review of supplier documentation, interviews with employees and managers, and on-site inspections.

- Specialized Assessment: specialized for each supplier and its population.

- Investigations: investigating the compliance of suppliers based on reports from supplier employees, NGOs or news.

- Capability Building: Apple works with its suppliers to develop holistically, correct non-compliance, and strengthen their management systems.

- On-going Training: Provides learning and developed opportunities by providing online educational resources.

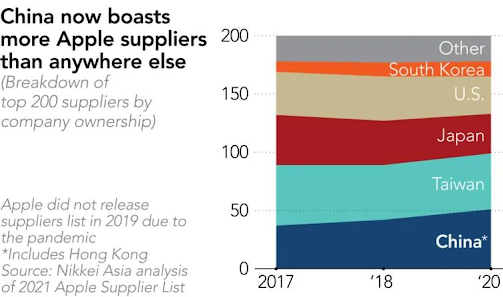

On the supplier side, according to the latest 2020 figures, among Apple’s top 200 suppliers, 51 are based in China (including Hong Kong). The rise of Chinese suppliers results from the country’s growing technological and manufacturing capabilities.

Nevertheless, to be named as Apple’s supplier, meeting high-standard is not enough, it also needs a tactic: “competitive pricing”. Chinese suppliers win orders by offering very low prices to Apple that non-Chinese suppliers can hardly imagine. They are willing to accept low margins that other suppliers don’t want to accept, however, these suppliers can gradually level up by working with Apple and then winning bigger contracts.

And Vietnam is not outside of this great game. The number of Apple suppliers in Vietnam increased to 21 last year from 14 in 2018, when the US-China trade war broke out and Vietnam was considered one of the top choices for the China +1 Strategy (gradually shifting production out of China to neighboring countries). 7 of those 21 are owned by companies based in China or Hong Kong. Among the AirPods assemblers are Luxshare Precision Industry and GoerTek, both of which have been manufacturing wireless headphones in Vietnam since early 2020. Most of the Apple-certified factories are in North Vietnam.

For key suppliers, Apple always gives priority to signing long-term contracts, and using its “abundant” cash source to make a deposit in advance to negotiate at the lowest cost with the largest amount of stock, to ensure strategic materials are readily available under all circumstances. Some electronic components are procured from exclusive suppliers or from limited sources. Apple takes all possible measures to ensure its priority.

The above analysis shows Apple’s focus on procurement activities, reflected in its strategy to establish and maintain relationships with suppliers. Each supplier is an important link in the entire supply chain and in order to maintain their competitiveness as well as the brand in the market, it is a must of Apple.

Nhat Huyen

FURTHER READING: